Illuminate Your World: The Magic of Acrylic LED LGP Sheets

Date:

28 Jun,2025

Illuminate Your World: The Magic of Acrylic LED LGP Sheets Table of Contents What Are Acrylic LED LGP Sheets? Benefits of Acrylic LED LGP Sheets How Acrylic LED LGP Sheets Work Applications of Acrylic LED LGP Sheets Choosing the Right Acrylic LED LGP Sheet Installation and Maintenance of Acrylic LED LGP Sheets Comparison with Other Lighting Solutions The Future of

Illuminate Your World: The Magic of Acrylic LED LGP Sheets

Table of Contents

- What Are Acrylic LED LGP Sheets?

- Benefits of Acrylic LED LGP Sheets

- How Acrylic LED LGP Sheets Work

- Applications of Acrylic LED LGP Sheets

- Choosing the Right Acrylic LED LGP Sheet

- Installation and Maintenance of Acrylic LED LGP Sheets

- Comparison with Other Lighting Solutions

- The Future of Acrylic LED LGP Technology

- FAQs About Acrylic LED LGP Sheets

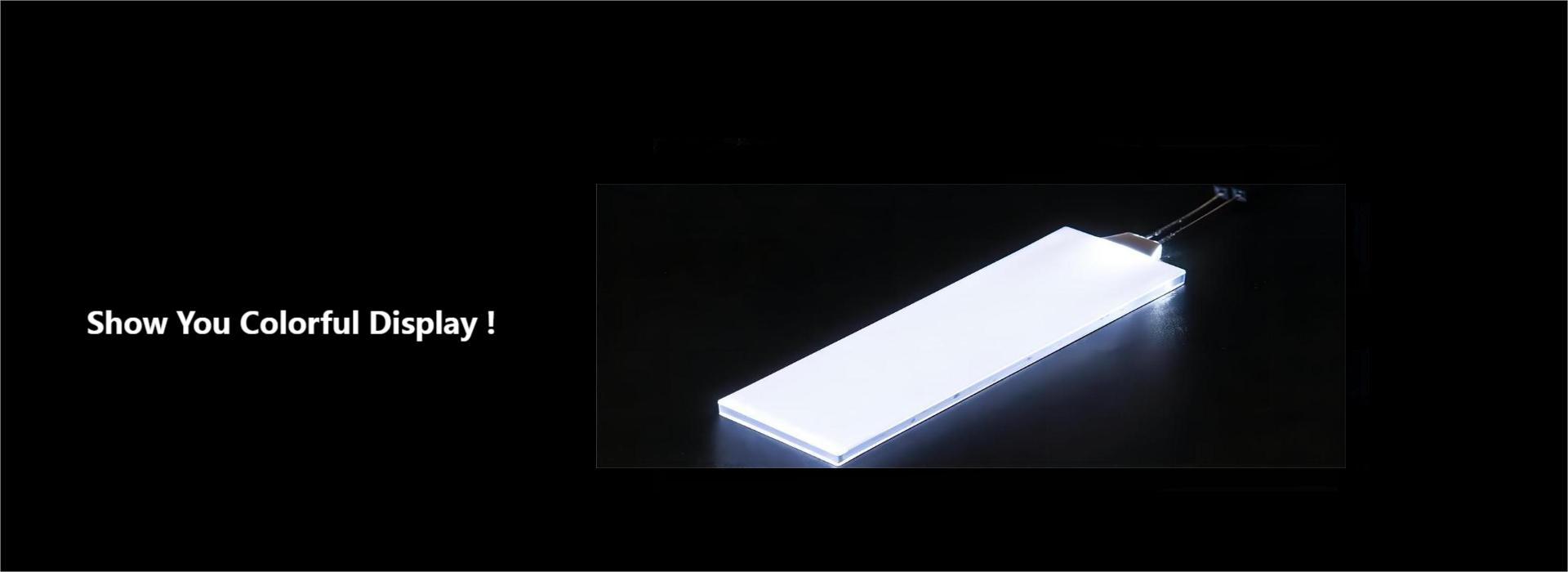

What Are Acrylic LED LGP Sheets?

Acrylic LED light guide plates (LGP) are advanced lighting solutions designed to distribute light evenly across a surface. Made from high-quality acrylic, these sheets play a crucial role in various lighting applications, particularly in LED-based systems. They function by taking the light emitted from LEDs and guiding it through the sheet, resulting in a uniform illumination effect. This technology not only enhances visual appeal but also improves energy efficiency.

The Composition of Acrylic LGP Sheets

Acrylic LGP sheets are primarily composed of polymethyl methacrylate (PMMA), known for its excellent light transmission properties. The material is lightweight, durable, and resistant to yellowing over time, making it ideal for long-term use in lighting applications. Their optical characteristics facilitate the efficient diffusion of light, ensuring that the brightness is evenly distributed without hotspots.

Benefits of Acrylic LED LGP Sheets

Acrylic LED LGP sheets offer a multitude of benefits, making them a popular choice in the lighting industry. Here are some of the key advantages:

1. Energy Efficiency

One of the most significant benefits of acrylic LED LGP sheets is their energy efficiency. By effectively guiding light, these sheets reduce the need for multiple light sources, leading to lower energy consumption and reduced electricity costs.

2. Enhanced Aesthetics

With the ability to produce soft, diffuse lighting, acrylic LGP sheets enhance the aesthetic appeal of any space. They create a modern and sleek look, making them suitable for various applications, including commercial and residential settings.

3. Versatility

Acrylic LGP sheets are highly versatile and can be customized to fit different shapes, sizes, and lighting requirements. Whether for backlit displays, signage, or general lighting, these sheets can adapt to various design needs.

4. Durability

Unlike traditional glass, acrylic LGP sheets are shatter-resistant and less prone to breakage, making them a safer option for many applications. Their resilience ensures longevity, reducing replacement costs over time.

5. Easy Installation

These sheets are lightweight and easy to handle, simplifying the installation process. With minimal tools and expertise, they can be mounted in various settings, allowing for quicker project completion.

How Acrylic LED LGP Sheets Work

The operation of acrylic LED LGP sheets is fascinating yet straightforward. Here’s how they function:

The Light Input

The process begins with LED lights mounted along the edges of the acrylic sheet. These LEDs emit light, which is then absorbed by the acrylic material.

Light Guiding Mechanism

As the light enters the acrylic sheet, it is refracted and redirected through the material. The unique design of the sheet, often featuring micro-structures or dots on one side, helps scatter and diffuse the light evenly across the surface.

Distribution of Light

The result is a uniform distribution of light that enhances visibility and ambiance. This mechanism allows for a variety of lighting effects, from soft ambient lighting to brighter task lighting, depending on the application and design.

Applications of Acrylic LED LGP Sheets

The versatility of acrylic LED LGP sheets opens up a wide range of applications across different industries:

1. Commercial Lighting

In retail and office spaces, acrylic LGP sheets are used for backlit signage, ceiling panels, and decorative lighting features. They create inviting atmospheres that attract customers and enhance productivity.

2. Residential Design

Homeowners use acrylic LGP sheets in various ways, such as in kitchen under-cabinet lighting, bathroom fixtures, and custom light installations. Their aesthetic versatility allows them to blend seamlessly with various interior styles.

3. Automotive Lighting

Acrylic LGP sheets are increasingly popular in automotive lighting, including dashboard illumination and ambient lighting features, providing both functionality and a modern touch to vehicle interiors.

4. Architectural Features

Architects and designers utilize acrylic LGP sheets in innovative ways, incorporating them into lighting fixtures, partitions, and ceilings, thereby creating striking visual elements in commercial and residential buildings.

Choosing the Right Acrylic LED LGP Sheet

When selecting acrylic LED LGP sheets for your projects, certain factors need to be considered to ensure optimal performance:

1. Thickness of the Sheet

The thickness of the acrylic sheet can influence its light transmission and diffusion. Thicker sheets may provide more durability, but may also limit light dispersion. It’s crucial to find a balance based on application needs.

2. Surface Texture

Different surface textures, such as frosted or clear finishes, can affect how light is distributed. Frosted surfaces typically provide softer, diffused lighting, while clear finishes allow for higher brightness levels.

3. Size and Shape

Ensure the selected acrylic LGP sheet fits the intended design space. Custom sizes and shapes can be manufactured to meet specific project requirements.

4. Compatibility with LEDs

Check the compatibility of the acrylic sheet with the LED lights being used. The light output and color temperature of the LEDs can impact the overall lighting effect achieved.

Installation and Maintenance of Acrylic LED LGP Sheets

Proper installation and maintenance are essential for maximizing the longevity and effectiveness of acrylic LED LGP sheets:

1. Installation Guidelines

Follow manufacturer guidelines during installation to ensure optimal performance. Use appropriate mounting techniques, such as adhesive or clips, and ensure that the LEDs are securely positioned along the edges for even light distribution.

2. Cleaning and Care

To maintain the clarity and integrity of the acrylic sheets, regular cleaning is necessary. Use mild soap and water, avoiding abrasive materials that could scratch the surface. Regular maintenance will help preserve the sheet’s optical properties over time.

Comparison with Other Lighting Solutions

Acrylic LED LGP sheets stand out among various lighting solutions. Here's a comparison with traditional options:

1. Compared to Fluorescent Lighting

Fluorescent lights are less energy-efficient and often provide uneven lighting. Acrylic LGP sheets offer better light distribution and consume less energy, making them a more sustainable choice.

2. Compared to Halogen Lighting

Halogen lights produce significant heat and can be inefficient. Acrylic LGP sheets, in conjunction with LEDs, remain cool while providing adequate illumination, ensuring safety and cost savings.

The Future of Acrylic LED LGP Technology

The future of acrylic LED LGP technology looks promising as innovations continue to emerge:

1. Advancements in Materials

Research into new acrylic composites and additives is ongoing, aiming to enhance light transmission and durability. This will lead to even more efficient lighting solutions.

2. Integration with Smart Technology

As smart home technology advances, acrylic LED LGP sheets are expected to integrate more seamlessly with smart lighting systems, offering customizable and adaptive lighting solutions for modern spaces.

3. Sustainability Initiatives

The trend toward eco-friendly materials will likely influence acrylic LGP production, focusing on sustainable sourcing and manufacturing processes to reduce environmental impact.

FAQs About Acrylic LED LGP Sheets

1. What is the lifespan of acrylic LED LGP sheets?

Acrylic LED LGP sheets can last for many years, typically around 10 to 20 years, depending on usage and environmental conditions.

2. Can I cut acrylic LED LGP sheets to fit my project?

Yes, acrylic sheets can be cut with appropriate tools. Ensure to follow safety precautions and manufacturer guidelines when cutting.

3. Are acrylic LED LGP sheets UV resistant?

Yes, high-quality acrylic sheets are resistant to UV rays, which helps prevent yellowing and degradation over time.

4. How do I know if an acrylic LGP sheet is compatible with my LEDs?

Check the specifications of both the acrylic sheet and the LED lights to ensure they match in color temperature and light output requirements.

5. Can I use acrylic LED LGP sheets outdoors?

While some acrylic LGP sheets are suitable for outdoor use, it is essential to select UV-resistant and weatherproof options to ensure durability in outdoor environments.

Conclusion

Acrylic LED LGP sheets represent a significant advancement in modern lighting technology. Their energy efficiency, aesthetic appeal, and versatility make them ideal for a wide range of applications. As we move towards a more sustainable future, the innovations in acrylic LED technology will continue to play a crucial role in enhancing our environments. By understanding their functionality and advantages, we can make informed decisions that illuminate our spaces effectively and beautifully.

Key words: LED Backlight LED Back Light Module Light Guide Plate LED/LCD Display